After recording last week’s podcast, I found myself still thinking about the old Singer sewing machine I’d mentioned – the one I was given on my twelfth birthday, the one that had been my mother’s. It had been put up in the loft of this house when we moved in, and shockingly, I worked out that as that was over two decades ago, I was still in my twenties at the time. At that point, I had a shiny, new Janome, and no use for the old Singer – but because it had been my mother’s, I kept it of course – along with her old photo albums, her letters to my Dad when she was (tragically unknowingly) terminally ill, and all the other things that are important to me and I want to keep, but don’t really know what to do with: I have no memories of my mother, so her “stuff”, her photos and the words she wrote for other people, is all I have. The sewing machine fell into the “too difficult” category – surplus to requirements, of no use to me whatsoever, but…..it’s my mother’s.

So on Saturday morning, after finishing the podcast edit, I pulled down the loft ladder and ventured upwards. I had to move various piles of plastic crates, and suitcases, and there it was. Obviously, I had no idea where the key was. It may have been on a ring with other keys from previous lives, kept more out of sentimentality than anything else, and then one day in a fit of Marie Kondo tidying I probably threw the whole lot away…but I really don’t remember.

Luckily, before I ventured loft-wards, I’d found a YouTube video on How To Open A Singer Sewing Machine Box Without The Key. A little screwdriver is the answer! It took a bit of persuading, and trying to shine my iPhone torchlight into the keyhole to see what I was doing, but then I was in. And there it was.

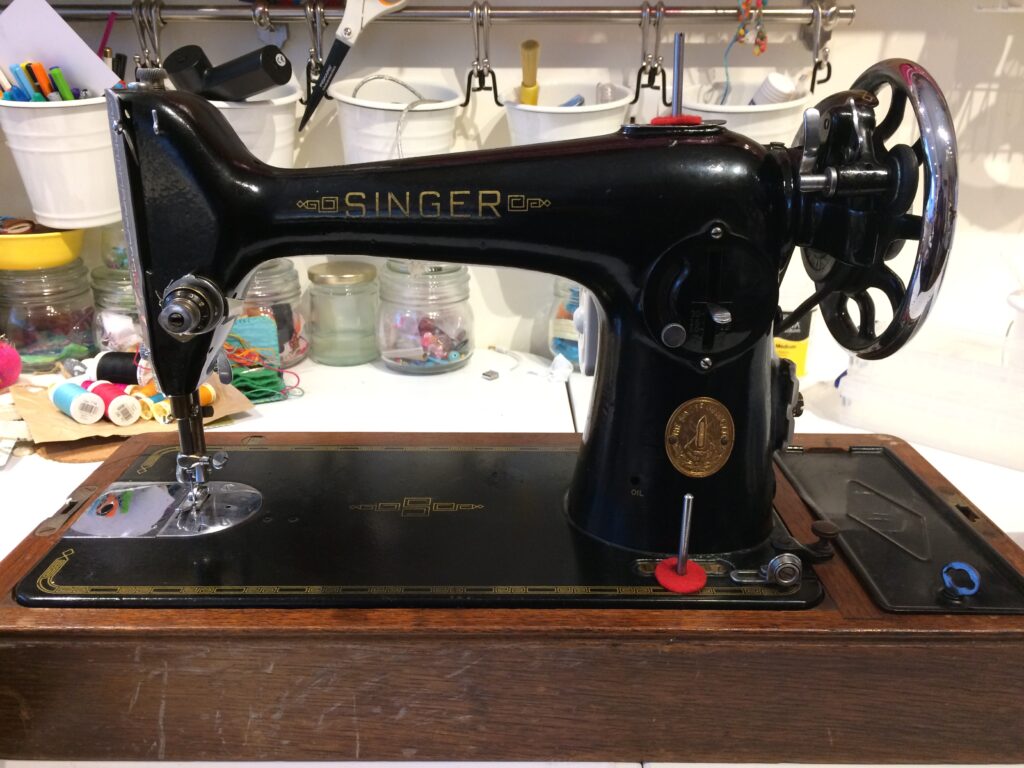

Everything was exactly as I remembered, and more so. The shellac coating had crazed during the twenty plus years of summer heat and winter cold, and when I rubbed at it, it came away in grungy yellow patches. The flex was damaged, with wires starting to pull out of the foot pedal, and nearer the motor a dangerous homemade insulation tape repair was peeling away. I went back downstairs for my husband’s head torch, then back up again to take a few photos, then I put the ladder away to ponder my next move.

By lunchtime, I’d decided: I want to get it down, to look at it properly. It was too dark and difficult in the loft to have a proper look at it, but a quick turn of the flywheel hinted that there was indeed something special about it: despite the years, it still turned incredibly smoothly.

So later that afternoon found my husband, Nick, at the bottom of the ladder, arms stretched above his head, supporting the not inconsiderable weight of the machine, and me kneeling at the top of the ladder, hanging downwards and holding onto the handle, and the sewing machine case wedged neatly between the loft hatch and the top rung of the ladder, both of us acutely aware that all that was holding the machine in the box were a couple of metal lugs on either side. A vision flashed through my mind of us stuck like that, in a domestic tableau, wondering how loud we would have to shout for the neighbours to hear and come to our rescue. But luckily, a bit of adjustment on the angle of attack, and it was out and down. It weighs a ton!

A quick Google of the serial number brought up the first big surprise: according to the number, the machine actually dates back to late 1948 – much earlier than I had supposed. And it immediately occurred to me – it wouldn’t have been my Mother’s machine, not at first, as she was only eight years old then. It must have been my Grandmother’s machine, bought after the war, and maybe when they moved to the family house in Harrogate. The house where she had her own sewing room half way up the stairs – and where I learned to sew. Google also informed me that the machine had come supplied with the motor already attached: I’d always assumed it was a later addition, and wondered if it had previously been a hand cranked machine. Of course, when the machine was put up in the loft, the internet was not really a thing – so I hadn’t known any of this, as there was no way of ever finding it out.

Once on the dining room table, I was able to clean up the worst of the shellac with a soft cloth, and quickly determined that there was no way I was going to be plugging anything into the mains. But turning that flywheel – so smooth! Which made it oh so tempting to see if it would stitch. Except of course, the bag of bits – all the bobbins, accessories, obscure metalwork – the same collection of bits that may have contained the key – had also been lost in the mists of time.

So I started to turn my whole studio upside down – repeatedly going back to the drawers that seemed like the obvious place I would have put the ancient Singer’s accessories for safe-keeping – but in reality, hadn’t. I went back up to the loft, several times, delving into boxes, but still no joy. I did find Mother’s old photo negatives, which was good, as I’d had one horrible thought that I’d “tidied” them too. Then, I remembered that in my teaching kit, I had a small collection of various plastic bobbins that I kept on the off-chance somebody needed a spare. And lo, one of them seemed to fit OK. We were in business. And not only that, in my teaching bag I’d found a business card for Alex Askaroff – who I’d never met, but had recommended to various people over the years on the strength other people’s recommendations.

There’s more than enough explanation on his website of who and what Alex is and does, with links enough for you to get lost for months (we’ve just watched his fascinating “day in the life” video). Suffice to say, he knows sewing machines. Nick encouraged me to send him an email, just to see if there was anything he could do, and was as excited as me when we got a reply back almost within the hour, saying that not only would he be happy to look at it, but he would only need it for a few days, and that if he couldn’t fix it, there would be no charge at all.

It was an article about this machine on Alex’s website that told me everything about my machine that I had not known before: how it had been the top of the range machine, that one had been gifted to the young Princess Elizabeth as a wedding present when she married Prince Philip, and how later models – the lighter, aluminium ones – had been made from recycled Spitfires and Lancasters from the war. I’d had no idea I owned such a wonderful machine.

The next morning, I began the laborious process of winding the bobbin using the flywheel only. Once fitted, it was easy to see that the stitch was still pretty good, and the machine was still doing what it should – albeit in a slightly creaky and laboured way, as I was still not switching on any electricity, and could only stitch by turning the wheel by hand – with no hand crank. And as I don’t remember ever oiling the machine, I don’t think it had seen a drop since at least 1982.

And then the biggest adventure so far: we’d also discovered from our internet investigations, that it was possible to drop the teeth on this model of machine (201K). After a bit of headscratching, and some persuasion with a large screwdriver, we worked out how to do it – probably something that had never been done before, or not for a very, very long time.

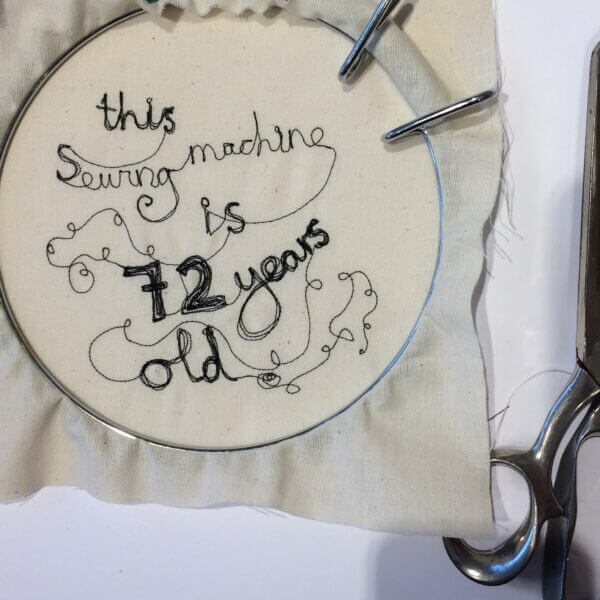

And so to try it! I didn’t have an embroidery or darning foot that fitted, and I was still hand-cranking using the flywheel, but I did manage to get some machine embroidery stitched. It was a laborious old job, but filmed and speeded up it looked quite realistic – even if it gave everyone on Instagram and Facebook the heebyjeebies!

On Monday, after waiting for the frost to clear off the car, we took it to Alex in Eastbourne. And by Wednesday morning, he sent an email saying that he’d finished – new motor, full service, and not only had he furnished it with new bobbins, he’d also found a key, an original box of bits – including the ruffler! – and an original instruction manual, only missing the first page. I was over the moon, and couldn’t wait to try it.*

As soon as we got it home, I plugged it in….and it’s wonderful! It stitches so smoothly and beautifully. On the Saturday evening, I’d found an embroidery foot on the Singer website, and paid extra for speedy delivery. I immediately tried it out – perfect fit – and then grabbed a bit of calico and stitched this: and once again, it seems to have become a little viral internet hit! Here’s the YouTube version; the original video I put on Facebook has had nearly 2 million views now. People really like watching free motion embroidery!

And so that would have been the end of the story…if it wasn’t for a chance discovery on Friday evening. Nick had walked down to town at the end of the day to collect our car from the garage: it had been in for it’s MOT and boringly but predictably, it had failed. So it was later in the day than he’d planned when he eventually went down to collect it, after waiting for the repairs to the suspension. He took the short cut to the garage, past the little sewing shop in the market place – somewhere he’d never taken any notice of before. And lo, in the window, there was a beautiful old Singer sewing machine. A hand cranked one, and smaller than mine. If we hadn’t spent the week occupied with my old machine, there’s no way he would have noticed let alone know that it was a “find”. So it was funny that he forgot all about it, until about 9.30pm, when he suddenly remembered! I sent a quick Facebook message to the shop expressing interest, checked to see what their (limited) opening hours were, and then we went down first thing on Saturday.

It was awkward, trying to look at it properly – there are obviously tight restrictions on who can enter the shop, at the moment. But it didn’t really take much deliberation to know that it absolutely had to come home with us. I bought a few extra Gutermann threads while I was there, and was allowed to nip across the empty shop to pick out the colours instead of trying to describe them from a distance – and we agreed that if anyone asked, I was their Saturday Girl!

Once home, we gave the new machine – new in 1908 – a spin. And I think if anything, it’s even more beautiful and smooth to operate than my 201K. Nick even had a little go on it too – and now I think it’s going to be his machine. He wants to make a waistcoat! He has his own little video on Facebook, and that’s had a few thousand views, too.

I think Gina and I have definitely started something here. All week, we’ve had messages from people telling us about their old and vintage machines, and one good friend has even scoured eBay for her childhood machine! It really goes to prove: new is not always better, and good craftsmanship lasts.

*I asked Alex how often I should oil it: “about every 10,000 years”.

9 Thoughts to “Hidden Treasure”